From Site to Sale: How Automation Is Cutting Construction Delays- Key Highlights

- Construction delays caused by weather, labour shortages, procurement gaps, and poor coordination are being reduced by up to 30% through automation.

- Automation now spans the entire construction lifecycle—from planning and design to site execution, handover, and sale, making faster delivery a strategic advantage.

- AI-driven, intelligent workflows are replacing reactive management by enabling real-time monitoring, predictive scheduling, and early risk detection.

- Technologies such as BIM, robotics, drones, prefabrication, and smart procurement are improving productivity, quality, safety, and cost certainty.

- India is leading Asia-Pacific in construction digital adoption, with higher technology use translating into revenue growth, fewer safety incidents, and better project outcomes.

Delays in construction have always been part of the environment as built. Construction projects in residential, commercial, and infrastructure segments suffer from delays that result from the projects going over the time that has been laid down for them to be completed.

The causes of the construction delays, which are mainly considered, are weather disruptions, labor shortages, procurement inefficiencies, and coordination gaps. Besides, the delays have always been a burden in terms of costs, the rupture of the relations between the parties involved and the postponement of the developers and investors receiving their income.

Nonetheless, the construction industry is presently going through a fundamental change. Automation enabled by digital tools, artificial intelligence, robots, and data- driven systems is transforming how projects are planned, performed, and delivered. As manual processes that are fragmented are replaced by integrated and intelligent workflows through automation, it is estimated that the construction delays are reduced by at least 30%. Hence, besides the delay reduction, there are benefits to the quality, safety, and predictability.

This evolution is not merely the result of specific technologies or pilot research. Automation is gradually becoming a part of the entire construction lifecycle from the early stage of planning through site executing to handing over and selling which means that faster delivery is a strategic advantage that is hardly ever a lucky accomplishment.

What Construction Automation Really Means?

Construction automation is not only the automation of robots on site. Rather, it is a vast landscape of technology that aims to automate activities as much as it is possible.

At the core of automation is:

- Digitizing existing paper-based or manual work processes

- Applying Data and Algorithms in Forecasting Risks and Creating Timetables

- Automating repetitive, high-risk, or time-consuming site activities

- Integration of planning, procurement, execution, and monitoring programs into one digital platform

Rather than eliminating the involvement of humans, the aim is to enhance decision-making by humans, replace reliance on guesswork, and remove inefficiencies that end up causing delays.

Why Construction Delays Occur Without Automation?

Construction projects are highly vulnerable to delay as they are very complex and fragmented. At a particular point of time, a large number of stakeholders are involved, including developers, consultants, contractors, etc.

Common causes of delays:

- Static Planning Methods, Not Adapting to Real Traffic Changes

- Lack of site visibility in terms of receiving delayed or subjective progress reports

- Procurements uncertainty; that is, material shortages and logistics struggles

- Labor constraints, like skill shortages and safety shutdowns

- Reworking due to errors, design conflicts, or communication problems

The Shift from Manual to Intelligent Workflows

According to Fortune Business Insights, major companies are increasingly realising that traditional sales workflows characterised by a fixed stage, by, stage progression and lots of manual data entry are quickly becoming outdated. The legacy systems are heavily reliant on humans to trigger, oversee, and adjust processes; hence they are getting out of sync with the speed, scale, and complexity of sales environments nowadays.

As a result, innovative companies are completely rethinking the way they do sales work. Leading organisations have already transferred up to 50% of their non selling activities to shared services teams and continue to carry out routine task automation at a frenetic pace. This move has led to the creation of an extra 20% sales capacity, and consequent productivity gains of up to 30%, thus enabling sales teams to spend more time with customers and, ultimately, increase sales.

Yet, the change is much deeper than simple automation. AI, empowered sales tools are at present capable of analyzing huge amounts of structured and unstructured datafor instance, emails, call transcripts, CRM records, market signals in order to initiate the next step themselves. Such tools can automatically check deal health, risk forecast, and even suggest the best action, all without the need of waiting for the sales rep to manually input the data.

Generative AI is pushing this transformation even more. Using analysis of customer behaviour and past interactions, AI can pinpoint the best leads, rate them according to the probability of their conversion, and send ultra, personalized messages suitable for different buyer journey stages. Meanwhile, AI based input grading systems are constantly elevating data standards by alerting reps to call summaries that are too vague or incomplete and by co, creating on, the, spot enhancements as agents write up their interactions.

The effects of smart workflows are already taking shape in numbers. Salespeople who leverage AI powered automation report that their daily saving in work time was up to 2 hours and 15 minutes, which corresponds to 25% higher productivity of the entire team. To illustrate, a B2B company, which is in the sound technology business, cut the order entry processing time from three hours to only three minutes by implementing robotic process automation. Thus, the representatives were able to spend 30% more time with customers and the sales potential increased by 20%.

Looking at the future, the ability to be flexible is what will differentiate the most successful sales automation players. Standard sales models are held back by major bottlenecks, with sales staff spending up to 12 hours a week on tasks that can be done manually, which work out to be almost 60% of their total working time.

Come this, companies should incorporate modular, flexible workflows that can be reused, improved, and expanded as the business requirement changes. This kind of frame will make sure that the automation investment does not become obsolete even if the technologies and market dynamics change.

Why Automation Is Critical From Site to Sale?

Automation is changing not just the rate of construction but also the overall model of the real estate business.

- Faster Revenue Realization- Shorter construction periods also mean earlier completion of projects, earlier occupancy of premises, and hence earlier sales or leasing out of buildings.

- Improved Cost Certainty- Delays are one of the largest contributing factors to cost overruns. Automation helps manage timelines, which stabilizes the budget.

- Better Buyer Confidence- A consistent quality of service with timely delivery can contribute immensely to brand credibility, which remains a fundamental factor in residential real estate.

- Scalability for Developers- Automation enables companies to undertake several projects at one time without increasing their management levels proportionately.

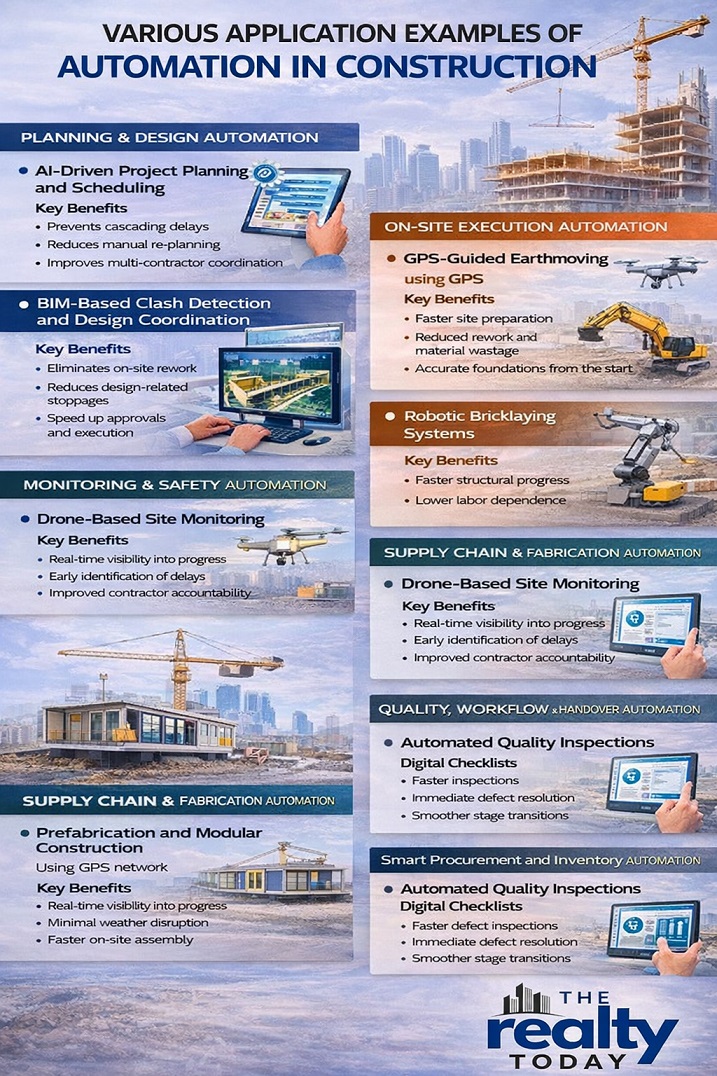

Key Technologies Driving Construction Automation

1. Building Information Modeling (BIM)

Building Information Modeling (BIM) helps in developing a digital model of the building where architectural, structural, and MEP systems are majorly coordinated and integrated into a single coordinated environment. BIM, which facilitates early clash detection, faster design approvals, 4D scheduling, and better collaboration among stakeholders, identifies issues for resolution before construction, thereby greatly reducing rework and time delays on site.

2. Artificial Intelligence and Machine Learning

AI and machine learning technologies take project data, both historical and real, time, in a very large quantity, and run analytics to enhance the accuracy of planning and the efficiency of the execution. Such systems not only forecast schedule risks but also help to put the activities in the best possible order, diagnose the points where productivity is reduced, and predict the consequences of a delay, therefore they continuously improve the results as they get new data from the project performances.

3. Automated Site Monitoring and Reality Capture

By using drones, fixed cameras, IoT sensors, and mobile reporting tools, the construction site progress tracking can be completely or partially automated. These systems collect real time data and based on the actual progress they check with the planned schedule and generate an objective report. They provide early warnings to the site managers about the deviations from the plan so that the corrective action can be taken without having to wait for the manual reports.

4. Robotics and Autonomous Equipment

Nowadays, robotic solutions and autonomous machines are more and more extensively utilized for tasks that require high repetition and high precision, e.g., bricklaying, concrete finishing, rebar tying, welding, and GPS, guided earthmoving. Such solutions help to increase the output of work, to improve the precision, to lower the dependency on labor, and to shorten the time of the whole project while safety is better.

5. Prefabrication and Modular Construction

Due to automation, the trend of prefabrication and modular construction has rapidly increased. Prefabrication is a process in which building parts are produced in a factory under controlled conditions and then shipped to the site for assembly. This allows the two processes, manufacturing and site work, to be done at the same time, thus cutting the overall project timeline. It also eliminates weather, related delays, guarantees consistent quality, and drastically reduces the time taken for on, site construction.

6. Smart Procurement and Supply Chain Automation

Smart procurement platforms automatically integrate material requisition with project schedules and thus equip them with real time delivery tracking and predictive shortage scenarios. They analyze supplier performance and anticipate disruptions, which helps keep material availability on a high level and prevents delays caused by supply chain inefficiencies.

7. Workflow Automation and Digital Approvals

A construction project is characterized by a large- scale documentation flow and thus approvals and regulation verification, which may restrain the implementation process. Workflow automation is a tool that can be used to simplify these tasks and it covers aspects like digital document management, automated approval cycles, mobile inspections, and real time compliance tracking. Hence, it can be expected that administrative barriers are reduced to the minimum, which normally hinder the progress on the site.

Applications across the construction lifecycle

- Planning and Design- Automation enables greater accuracy, decreases design blunders, and streamlines approvals.

- Execution and Site Management- Improved productivity and safety through real-time monitoring, robots, and equipment are observed.

- Quality Control- Automated inspections and digital checklists help to eliminate defects.

- Handover and Post-Construction- Digital documentation and asset data facilitate handover, maintenance planning, and occupancy.

Indian construction firms lead Asia-Pacific in digital technology adoption: Autodesk–Deloitte

Indian construction companies are taking the lead in adopting digital technologies in the Asia, Pacific region, which is highlighted in the State of Digital Adoption in Construction 2025 report by Autodesk and Deloitte. The report reveals that Indian companies are not only using a wider range of digital tools but are also making bigger investments in technology compared to their regional competitors, thereby turning digitalisation into real, measurable benefits in terms of revenue, safety, and operational efficiency.

- 54% of Indian construction firms are leveraging AI and machine learning

- Firms utilize a mean of 8.6 digital technologies, the most among the surveyed countries

- 35% of the total spending is going towards new technologies.

This level of adoption is indeed yielding real business results.

The report further reveals that companies with revenues above $100 million, the implementation of each new technology, correlates with an average revenue growth of $1.14 million.

Besides that, organisations that are more digitally mature have witnessed a 50% decrease in safety incidents, thus demonstrating how digital tools can help enhance safety and risk management on the site.

The most used technologies in India are data analytics (72%), construction management cloud software (66%), and mobile applications (66%)

BIM, IoT, and smart sensors are becoming very popular both in big and medium, sized projects

However, the report points out that a few challenges that may restrain the pace of the progress still exist.

Several, remaining key barriers, are the lack of digital skills among employees (36%), uncertainty around required technical capabilities (31%), and concern about the high cost of digital technologies (29%). Furthermore, limited access to technology providers and the pressure on budgets make the adoption even more complex.

Construction is a major contributor to the Indian GDP and is the source of employment for about 12% of the total workforce. Hence, the report highlights that the continuous deepening of digital technologies in this industry will mainly determine the success in safety, accuracy of project delivery, and the ability of the sector to sustain the economic growth over the years.

Challenges for Construction Automation Adoption

- High initial investment, especially for smaller firms

- Integration with legacy systems

- Adaptation of the workforce through reskilling and training

- Cultural resistance against shifting traditional workflows.

The Road Ahead

Automation will probably become a standard thing rather than a luxury as technologies develop and get cheaper. Understanding that faster and more reliable construction is crucial to meeting the needs of urbanization, housing, and infrastructure, governments, developers, and contractors are aligning themselves with the idea.

The industry is slowly moving towards a world where delays would no longer be considered an inevitable part of the production but something that can be easily resolved with the help of smart systems. Automation is transforming the construction industry from one that is reactive and delay, prone into a more predictable and data- driven. Using digital planning, AI, assisted decision making, robotics, and intelligent supply chains together can help projects reduce delays by 30% and at the same time achieve higher quality results.

Automation increases speed, certainty, and value creation in each phase of the process, from site execution to final sale. Automation is no longer simply a technology option but a strategic imperative for developers, contractors, and investors who are forward looking.

Image- freepik.com

.png)