Wall putty is a versatile fine powder used to prepare walls for painting or wallpapering in construction and renovation projects. Composed of a mixture of white cement, polymers, fillers, and additives, wall putty creates a smooth base coat that fills cracks and evens out irregularities on interior and exterior walls. Its primary function is to provide excellent adhesion to various substrates, ensuring a strong bond and preventing paint or wallpaper from peeling over time. Easy to apply and requiring minimal preparation, wall putty offers both functional and aesthetic benefits.

It acts as a protective barrier against moisture and stains, prolonging the lifespan of the finish, while also enhancing the visual appeal of walls with a clean, seamless finish. Available in different formulations to suit various project requirements, wall putty is an essential component of the painting and decorating process, valued for its durability, versatility, and ease of application.

Advantages of Wall Putty:

Surface Preparation: Wall putty plays a crucial role in preparing surfaces by filling in cracks, dents, and imperfections on walls. This preparatory step ensures that the surface is smooth and uniform, providing an ideal canvas for painting or wallpapering. By addressing surface irregularities, wall putty helps to achieve a flawless finish and enhances the overall aesthetic appeal of the walls. Additionally, a well-prepared surface ensures better adhesion of paint or wallpaper, resulting in a longer-lasting and more durable finish.

Adhesion: One of the key benefits of wall putty is its excellent adhesion properties. It forms a strong bond with various substrates, including concrete, plaster, brick, and gypsum board. This strong bond prevents paint or wallpaper from peeling or flaking over time, ensuring that the finish remains intact for an extended period. By providing a reliable base coat, wall putty helps to maintain the integrity of the finish and minimizes the risk of damage or deterioration, even in high-traffic areas or harsh environmental conditions.

Protection: In addition to improving adhesion, wall putty acts as a protective barrier, shielding the underlying surface from moisture, stains, and weathering. By filling cracks and sealing porous surfaces, wall putty helps to prevent water infiltration and moisture-related issues such as mold or mildew growth. Furthermore, the protective barrier offered by wall putty helps to maintain the structural integrity of the walls, reducing the risk of damage from external factors such as humidity, temperature fluctuations, or exposure to sunlight.

Ease of Application: Wall putty is known for its ease of application, making it a popular choice for both professional contractors and DIY enthusiasts. Its smooth paste-like consistency allows for quick and efficient application using a trowel or putty knife. Minimal preparation is required before applying wall putty, and it can be easily spread over the surface in thin layers. This streamlined application process saves time and labor costs, making wall putty an efficient solution for preparing walls before painting or wallpapering.

Aesthetic Enhancement: By filling imperfections and providing a smooth finish, wall putty enhances the overall appearance of walls, creating a polished and professional look. The uniform surface achieved with wall putty allows for a more even application of paint or wallpaper, resulting in a seamless and visually appealing finish. Additionally, the smooth texture of walls treated with wall putty enhances light reflection, brightening up interior spaces and making them appear more spacious and inviting.

Versatility: Wall putty is a versatile building material that can be used for both interior and exterior applications. Whether renovating a residential home or constructing a commercial building, wall putty offers flexibility in addressing surface imperfections and preparing walls for finishing. Its compatibility with a wide range of substrates makes it a versatile solution for various construction and renovation projects, providing consistent results across different surfaces and environments.

Longevity: Thanks to its durable properties, wall putty helps to maintain the integrity of the finish for an extended period. By providing a strong base coat that resists peeling, cracking, or flaking, wall putty helps to prolong the lifespan of paint or wallpaper, reducing the need for frequent touch-ups or repairs. This long-lasting durability ensures that the finish remains attractive and well-maintained, contributing to the overall value and aesthetics of the space.

Cost-Effectiveness: While wall putty may incur an initial investment, its long-term benefits outweigh the upfront costs. By preparing surfaces effectively and ensuring better adhesion of paint or wallpaper, wall putty helps to prolong the lifespan of the finish, reducing the need for frequent maintenance or repainting. This cost-saving advantage makes wall putty a cost-effective solution for enhancing the durability and aesthetics of walls, ultimately adding value to the property in the long run.

Types of Wall Putty

White Cement-Based Wall Putty: White cement-based wall putty is a versatile construction material used for preparing surfaces before painting. It consists primarily of white cement, fillers, polymers, and additives, which together create a smooth and uniform base for paint application. This type of putty is renowned for its excellent adhesion, durability, and water resistance, making it suitable for both interior and exterior surfaces. White cement-based putty effectively fills in cracks, dents, and imperfections, ensuring a flawless finish that enhances the aesthetic appeal of walls and ceilings. Its versatility and reliability make it a popular choice among contractors and homeowners seeking long-lasting and visually appealing paint finishes.

Acrylic-Based Wall Putty: Acrylic-based wall putty is formulated using acrylic polymers, providing flexibility and quick-drying properties. It is commonly used for interior surfaces, offering enhanced crack resistance and ease of application. Acrylic-based putty exhibits excellent adhesion and compatibility with various paints and coatings, making it a versatile option for different projects. Its quick-drying nature accelerates project timelines, allowing for faster completion and turnaround times. Contractors and DIY enthusiasts appreciate the convenience and efficiency of acrylic-based putty, which delivers professional-quality results with minimal effort.

Polymer-Modified Wall Putty: Polymer-modified wall putty combines the properties of white cement-based and acrylic-based putties to offer enhanced flexibility, adhesion, and water resistance. This type of putty is suitable for both interior and exterior surfaces, providing superior crack resistance and durability. Polymer-modified putty is known for its excellent workability, allowing for easy application and smooth finishing. It is often preferred for high-traffic areas and projects where long-term performance is crucial. Contractors appreciate its reliability and versatility, while homeowners benefit from its ability to maintain a pristine appearance over time.

Ready-Mix Wall Putty: Ready-mix wall putty comes pre-mixed and ready to use, eliminating the need for onsite mixing and reducing labor costs. This type of putty is convenient and user-friendly, making it ideal for small-scale projects and DIY enthusiasts. Ready-mix putty is available in various formulations, including white cement-based and acrylic-based options, catering to different project requirements. Its ready-to-use nature saves time and effort during the application process, allowing for efficient surface preparation. Whether used for minor repairs or extensive renovations, ready-mix wall putty provides a hassle-free solution for achieving smooth and uniform surfaces before painting...

Specialty Wall Putties: In addition to the standard types mentioned earlier, there are specialty wall putties designed for specific applications. These specialized putties address unique challenges and provide tailored solutions for various construction and renovation projects. For example, there are putties formulated specifically for repair and patching, which are ideal for fixing minor imperfections and damaged areas on walls and ceilings. Additionally, moisture-resistant putties are available for damp areas such as bathrooms and basements, providing protection against water damage and mold growth. Moreover, high-build putties are designed for filling larger voids and indentations, offering greater thickness and coverage compared to standard putties. Specialty wall putties offer specialized properties and performance characteristics to meet specific project requirements and ensure optimal results in challenging environments and conditions.

Applications of Wall Putty

Wall putty is used in both residential and commercial buildings, some common applications include:

1. Surface Preparation: Wall putty is primarily used for preparing surfaces before painting. It fills in cracks, dents, and imperfections on walls and ceilings, creating a smooth and uniform base for paint application. By providing a flawless surface, wall putty enhances the adhesion and longevity of paint, resulting in a professional-quality finish.

2. Repair and Patching: Wall putty is often used for repairing minor damages to walls, such as small holes or scratches. It can be applied to patch up damaged areas, ensuring a seamless transition between repaired and existing surfaces. Wall putty dries quickly and can be sanded down to achieve a smooth finish, making it an effective solution for minor repairs.

3. Moisture Protection: In areas prone to moisture, such as bathrooms, kitchens, and basements, wall putty can act as a protective barrier against water damage. Moisture-resistant putties are available for these applications, providing an additional layer of protection to the underlying wall surface and preventing issues like mold and mildew growth.

4. Decorative Finishes: Wall putty can also be used to create decorative finishes on walls, such as textured or patterned designs. By applying multiple layers of putty and using different tools or techniques, unique textures and effects can be achieved, adding visual interest to interior spaces.

5. Exterior Applications: While wall putty is commonly used indoors, certain formulations are suitable for exterior applications as well. Exterior-grade putties offer enhanced durability and weather resistance, making them suitable for use on exterior walls and facades.

Its ease of application and effectiveness make it a preferred choice among contractors and homeowners alike.

Market Potential of Wall Putty in India

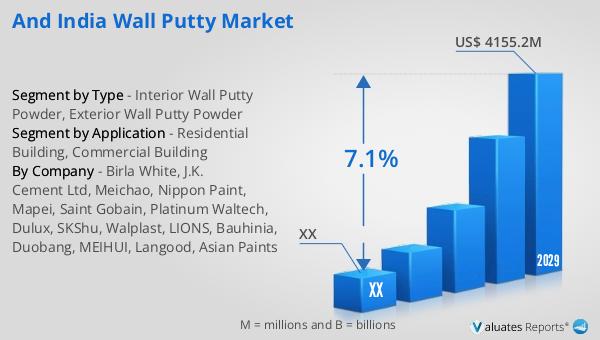

According to a Verified Market Research report, India's wall putty market was valued at USD 3.75 billion in 2019 and is projected to reach USD 6.45 billion by 2027, growing at a CAGR of 7.0% from 2020 to 2027.

Technavio estimates that India's wall putty market size will grow by USD 1.33 billion from 2022 to 2026 at a CAGR of 6%, with the residential sector having the largest market share. These market projections indicate significant growth opportunities for players in the wall putty market.

As per reports.valuates.com, in India, the Wall Putty revenue is expected to grow from US$ million in 2022 to US$ million by 2029, at a CAGR of % during the forecast period (2023-2029).

The growth of the market can be attributed to the increasing demand for Wall Putty owing to the Residential Building, Commercial Building Applications across the country. Several factors contribute to this growth trajectory. The proliferation of home décor projects, coupled with a rising demand for sustainable construction materials, presents avenues for innovation and market expansion. Additionally, the need for cost-effective painting solutions further fuels demand in the wall putty market.

Conclusion

Wall putty emerges as a pivotal component in the construction and renovation domain, offering a plethora of advantages that extend beyond mere surface refinement. Its capacity to create smooth, uniform surfaces lays the groundwork for impeccable paint finishes, thereby enriching the visual appeal of both interior and exterior spaces. From concealing imperfections to providing moisture resistance, wall putty demonstrates its versatility in tackling diverse challenges encountered in building maintenance and design. Moreover, its role in property staging and real estate enhancement underscores its importance in augmenting property values and attracting prospective buyers or tenants. As innovation continues to propel advancements in construction materials, wall putty remains a steadfast solution, seamlessly blending functionality with aesthetics.

.png)