Key Highlights – Chemical Anchors in Structural Applications

- Stress-free anchorage system: Chemical anchors rely on chemical bonding instead of mechanical expansion, eliminating radial pressure on concrete.

- Higher load-bearing capacity: Capable of carrying heavy structural loads even in low-strength, cracked, or ageing concrete.

- Edge-friendly performance: Ideal for close-to-edge and group fixings where mechanical anchors may cause splitting.

- Wide range of resin options: Polyester, unsaturated polyester, epoxy acrylate, pure epoxy, and hybrid systems allow precise selection based on load, environment, and curing time.

- Superior durability: Excellent resistance to creep, vibration, moisture, chemicals, and corrosion, making them suitable for harsh environments.

- Critical role in retrofitting: Highly effective for strengthening, rehabilitation, and post-installed rebar applications in existing structures.

- Seismic and safety compliance: Preferred choice in earthquake-prone zones due to reliable load transfer and long-term stability.

- Growing market adoption: Rising demand driven by high-rise construction, infrastructure expansion, stricter safety norms, and modern façade systems.

What Are Chemical Anchors?

The term "chemical anchor" refers to a type of fastening system in which the steel components (such as threaded rods, rebars, or bolts) are connected to concrete or masonry by means of resin based adhesives. The adhesive completely fills the drilled hole and chemically bonds the steel component to the substrate around it.

Apart from the fact that chemical anchors transfer load through adhesion instead of expansion, they:

- Do not exert radial pressure

- Minimise cracking risks

- Perform well near edges

- Offer flexibility in embedment depth

They are extensively used in various structural, industrial, and infrastructure applications, especially where safety and durability are of paramount importance.

Why Chemical Anchors Are Preferred Over Mechanical Ones?

The popularity of using chemical anchors in construction projects may be attributed to a number of performance advantages:

- High load-bearing capacity even in low-strength concrete

- Stress-free Anchoring, Less chance of Concrete Splitting

- Suitability for close-to-edge and group fixings

- Compatibility with cracked and uncracked concrete

- High durability in harsh and corrosive environments

Different Types of Chemical Anchors Used in Buildings

Polyester chemical anchors are considered to be the cheapest and easiest to use among other anchoring systems. They are composed of a two, component resin that blend while being injected and harden in a very short time under normal conditions. Usually, polyester anchors find application in fixing of staircases, handrails, faade brackets, pipelines, and light structural elements, requiring medium, load and dry uncracked concrete. Their rapid setting time makes them perfectly suitable for general construction and interior finishing works.

Unsaturated polyester chemical anchors represent a sophisticated version of traditional polyester systems and come in styrene, based and styrene, free forms. They provide stronger bonding, less odour, and better environmental performance as compared with standard polyester anchors. These products can be used both in masonry and uncracked concrete, and higher load can be expected from them than from regular polyester anchors. Depending on the composition, unsaturated polyester anchors can also serve for moderate structural fixings and post, installed rebar connections.

Epoxy acrylate chemical anchors are the high, quality anchoring systems that are purposely made for harsh construction settings. Such anchors normally are free from styrene and thus, offer fast curing along with a high load capacity. Epoxy acrylate resins are very suitable for wet, humid and chemically aggressive environments, including underwater applications. They are usually used for heavy, duty fixings in faades, industrial

Pure epoxy chemical anchors stand out as the most durable and dependable chemical anchoring systems in the market. These anchors have been specially designed to meet the needs of structurally severe applications and are therefore suitable for use in both cracked and uncracked concrete conditions, including earthquake zones. With pure epoxy anchors, you can get a bonding strength of the order of the highest level as well as excellent creep resistance and overall long term stability under constant loads. Structural steel connections, post, installed reinforcement, bridges, and other infrastructure components where safety and durability cannot be compromised are just a few examples of the widely diversified areas where such anchors are usually employed.

Hybrid chemical anchor systems aim to unify the two worlds of resin types: the polyester, based fast curing resins and the high, performance epoxies. The goal is to produce anchors that can be loaded quickly and at the same time give a strong and durable hold to the substrate. Installation of steel beams, columns, racking systems, fencing, and sound barriers is made easy with the usage of these hybrid anchors. Retrofitting jobs, in which installation speed and performance are the two key factors, can take full advantage of the characteristics of hybrid chemical anchors.

The increasing use of chemical anchors is mainly because construction projects are becoming more and more complicated. The demand for chemical anchors has gone up due to the combined effect of such elements' use of the high, rise buildings, infrastructures, faade systems, and seismic designs. Chemical anchors are most beneficial for renovation and strengthening works since they can handle situations where the quality of the existing concrete is doubtful, and mechanical anchors can cause cracking.

Application Areas of Chemical Anchors in Construction

• Structural steel connections: Fixing steel columns, steel beams, base plates, brackets, and trusses on the foundation of residential, commercial, and industrial buildings made of concrete

• Applications of post-installed rebar in structural extension, slab connections, beam connections, column strengthening, seismic retrofitting, RCC rehabilitation, etc.

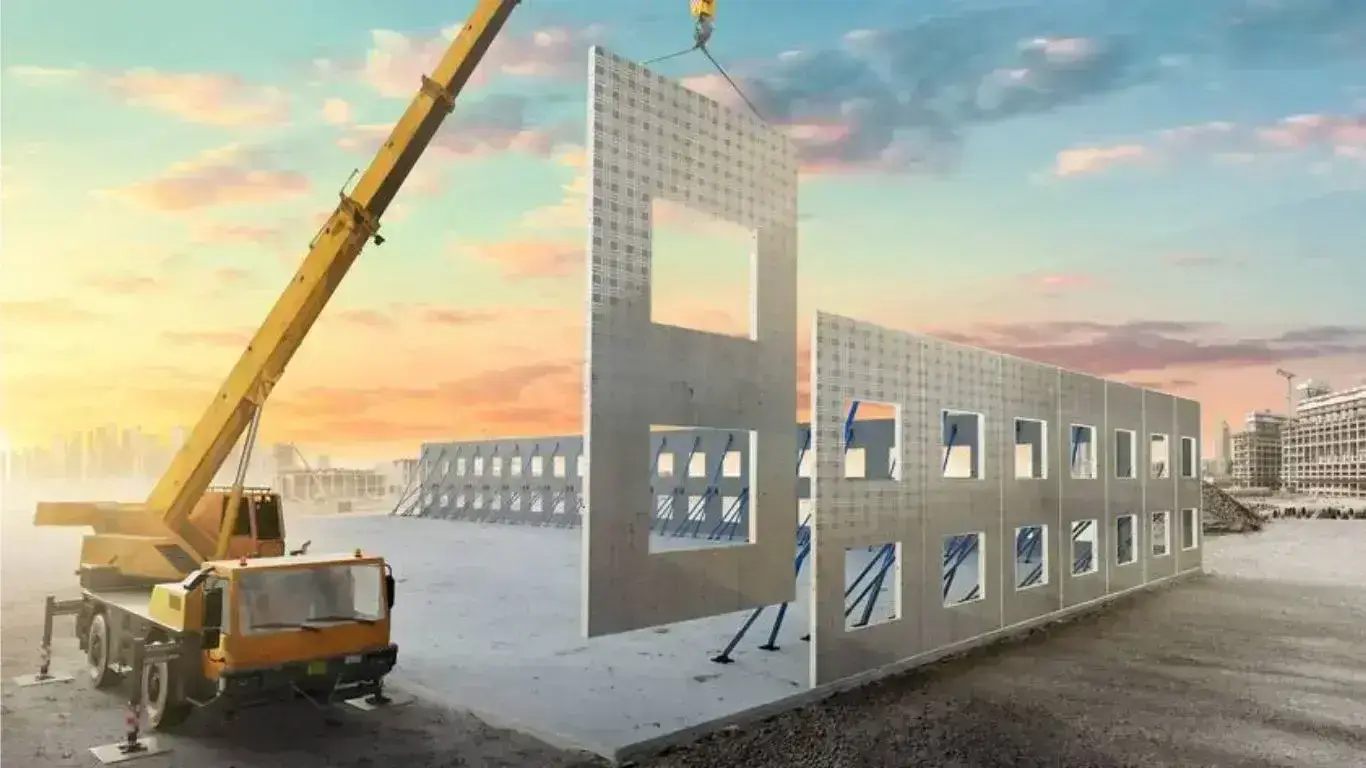

• Facade and cladding works such as curtain walls, stone claddings, aluminium composite panels, glass facades, and architectural brackets for high-rise buildings

• Industrial and plant installations for the anchorage of heavy industrial equipment, equipment mounting, cranes, conveyors, storage racks, and vibrating equipment.

• Infrastructure such as bridges, flyovers, metro construction, tunnels, retaining walls, highway structures for fixing crash barriers, noise barriers, signage, lighting poles, etc.

• Mechanical, Electrical, and Plumbing (MEP) services such as anchoring of cable trays, HVAC ducts, pipelines, fire fighting systems, supports, and suspended services

• Masonry and restoration works related to brickwork, blockwork, and stone used in construction, especially in repair, renovation, and restoration in heritage sites

• Safety and access equipment such as handrails, guardrails, staircases, balustrades, fencing systems, and fall protection equipment

• Solar panel mounting systems for the rooftops of buildings and industrial sheds, where a strong vibration-resistant anchorage is a necessity

Factors Driving the Growing Demand for Chemical Anchors

The use of chemical anchors is rising quickly with the changing construction practices. Key demand drivers include:

- Growth in high-rise and infrastructure projects

- Increased emphasis on structural safety and seismic resistance

- Increasing use of retrofitting and rehabilitation

- Need for anchoring in low quality or unknown concrete

- Adoption of modern Façade and MEP systems

- As buildings get more complex, the reliability of chemical anchoring systems is more vital.

Market Potential

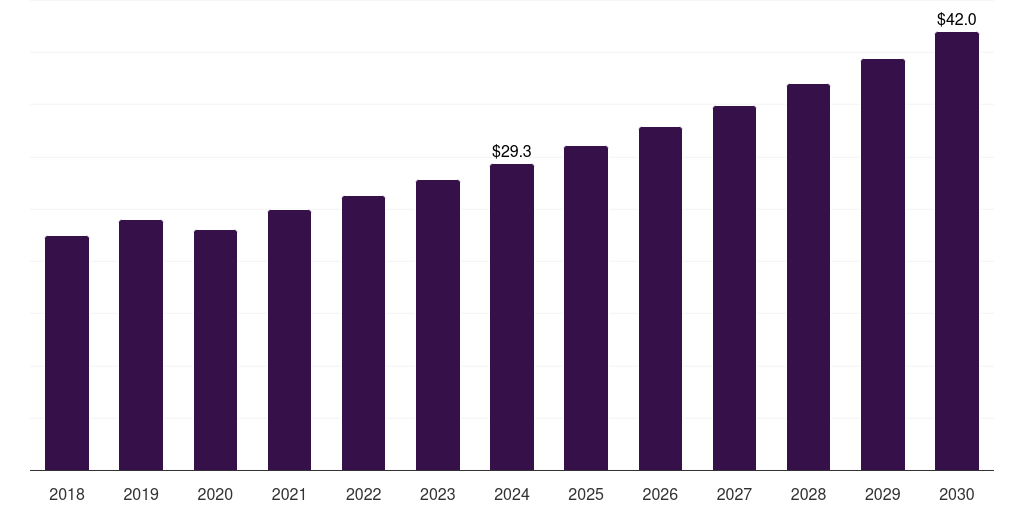

According to Grandview Research, chemical anchor market in India is experiencing a steady and structurally driven growth with the support of the expansion in construction activities in infrastructure, commercial real estate, and industrial projects. The market recorded a revenue of USD 29.3 million in 2024 and is expected to reach USD 42.1 million by 2030, with a CAGR of 6.2% during 2025, 2030. This growth path demonstrates the increasing use of high, performance fastening solutions in seismic zones, retrofit projects, metro rail networks, highways, airports, and large public infrastructure programs. In 2024, India took a share of about 2.9% in the global chemical anchors market, however, it is the fastest, growing market in the Asia Pacific region driven by rapid urbanisation, stricter construction safety regulations, and the growing preference for advanced anchoring systems over traditional mechanical anchors.

From a product perspective, the Indian market for injectable adhesives was quite sizable in 2024, with these adhesives making up more than 76% of the total revenue. This was mainly due to their multifunctionality, increased load, bearing ability, and compatibility with a wide range of substrates like cracked concrete, masonry, and rebar connections. Nevertheless, capsule adhesives are anticipated to be the segment with the fastest growth over the next few years. This is mainly because of the simple installation, correct dosing, and increased application in heavy, duty and quick turnaround construction scenarios, which are the major factors contributing to the growth of this segment.

Key Domestic Indian Manufacturers and Suppliers of Chemical Anchors

- Ripple India is a leading domestic manufacturer of injectable chemical anchoring systems and rebar fixing solutions, with a strong presence in infrastructure, industrial, and structural retrofit projects across India.

- Fosroc India manufactures chemical anchoring systems and a wide range of construction chemicals in India, serving large infrastructure, transportation, industrial, and commercial developments.

- Pidilite Industries offers structural adhesives, anchoring solutions, and bonding systems, supported by an extensive dealer and applicator network across residential, commercial, and light industrial markets.

- Dr. Fixit (Pidilite brand) provides anchoring, bonding, and repair products widely used in repair, retrofitting, and waterproofing-related construction applications.

- MYK Schomburg India produces anchoring and repair mortars locally, catering to metro rail, road, tunnel, water, and urban infrastructure projects.

- Sika India manufactures chemical anchors and anchoring resins in India, delivering solutions aligned with Indian standards and project-specific requirements for major infrastructure and industrial developments.

- Hilti India supplies high-performance chemical anchoring systems and post-installed rebar solutions, widely specified in large infrastructure, metro, industrial, and high-rise projects, supported by strong technical design support and on-site engineering services.

Other Notable Players in the Indian Market

- BASF India Construction Chemicals (now part of MBCC Group legacy products) has historically supplied chemical anchoring and repair solutions, with products still widely referenced in specifications and existing projects.

- Fairmate Chemicals offers anchoring adhesives and construction chemical solutions with growing adoption in repair, retrofit, and mid-scale infrastructure works.

- STP Limited provides construction chemicals including anchoring and bonding solutions, primarily serving infrastructure, industrial, and waterproofing-intensive projects.

- Ardex Endura India supplies specialized repair mortars and anchoring products, with increasing focus on premium residential, commercial, and industrial applications.

Way Forward

Chemical anchors are one of the major inventions of construction industry to change the way fastening and anchoring are done in modern buildings. Instead of creating mechanical expansion pressure, chemical anchors transfer loads through chemical adhesion resulting in stress, free anchorage, higher load capacity, and dashing performance at edges and in weak or cracked concrete. Therefore they can be considered more safe and reliable than mechanical anchors for heavy structural applications.

As the practice in the construction industry changes towards taller buildings, heavier loads, and tighter safety regulations, chemical anchors will inevitably become more and more popular. The fact that their performance has been confirmed, that they will last for a long time, and that they can be designed in many different ways are the reasons why chemical anchoring systems will be considered one of the most important parts of structural engineering for a safe, efficient, and future, ready built environment.

Images- alphatec-engineering.com, akfix.com

.png)