Key Highlights: Sustainable Alternatives to Cement and Concrete

- Cement’s Environmental Impact: Traditional Portland cement contributes ~8% of global CO₂ emissions, making sustainable alternatives urgent.

- Low-Carbon Substitutes: Materials like LC3, fly ash, GGBS, geopolymer concrete, and hempcrete reduce emissions by 40–80% while improving durability and performance.

- Circular Economy Benefits: Many alternatives repurpose industrial byproducts and agricultural waste, reducing landfill pressure and conserving natural resources.

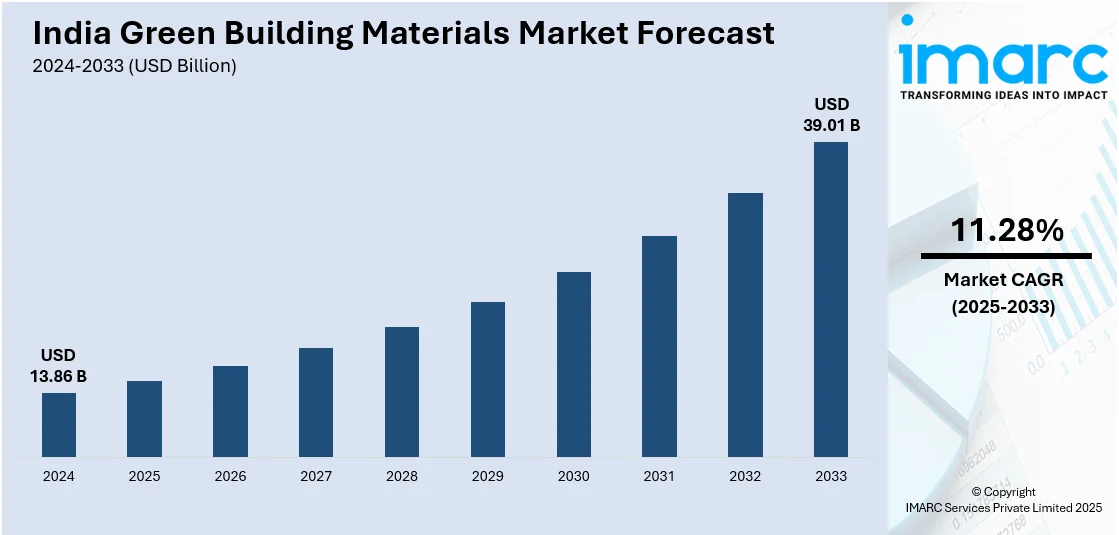

- Green Building Growth in India: The GBM market reached USD 13.86 billion in 2024 and is projected to grow rapidly, driven by certifications like IGBC and LEED.

- Successful Real-World Applications: Projects such as Noida International Airport (LC3), IIT Indore geopolymer research, NTPC ash-based houses, and IISc Bengaluru pilot projects demonstrate scalable, low-carbon solutions.

Cement and concrete are the major construction materials that has shaped indrastrcture across the world. From towering skyscrapers and bridges to highways, tunnels, and dams, concrete and cement are the go-to materials that has enable modern civilization to reach new heights. At the same time, the environmental degradation of traditional cement and concrete is also extremely high.

The production of Portland cement alone causes almost 8% of the total CO2 emissions recorded globally, which at the same time is the biggest cause of climate change due to industrial processes. The increasing population of the world, expected to reach the levels of 10 billion, coupled with urbanization, will require the need for more materials of construction, thereby increasing the quantity of the use of cement and concrete. This is the point where the problem begins.

Shift Towards Alternative Green Materials

According to the IBEF report, the construction sector in India is booming, with over 35 billion square feet of new built space expected by 2050, which will be double the 2025 stock, as per the GBM Market Study Report 2025. Residential and commercial sectors lead to approximately 25% of India's carbon emissions, of which cement and steel manufacturing processes make up 8% and 12% respectively. Brick kilns emit around 65 million tonnes of CO annually, which is 2.5% of the total emissions in the country.

Besides this, India produces around 150 to 500 million tonnes of construction and demolition (C&D) waste each year, out of which less than 1% is recycled. All these issues point towards the need for environmentally friendly building materials.

According to the GBM Market Study Report 2025, India's GBM market is expected to grow at a compound annual growth rate (CAGR) of 10% to 12%, reaching Rs. 6, 15, 090 to Rs. 7, 02, 960 crore (US$ 70, 80 billion) by 2030. The rise follows two tracks: the established manufacturers are making their value chains eco, friendly (for instance, low, carbon cement or recycled glass), whereas the startups are causing disruptive innovations (for instance, geopolymer concrete, waste, based pavers, 3D printed constructions, and agro, fibre panels). Major corporations are making ambitious commitments, Ambuja Cement is set to get 60% of its power from renewable energy by 2030, and UltraTech Cement is now using a carbon price of Rs. 882.54 (US$ 10) per tonne CO for its investment decisions.

Globally, for example, Sweden's H2 Green Steel is a pioneer, aiming to supply 2.5 million tonnes per year of hydrogen, produced "green steel" by 2030, thus indicating the future demand trajectory.

The key to the solution is in sustainability alternatives of cement and concrete. Scholars, engineers, and inventors all over the world are turning to materials and ways that help lower carbon emissions while at the same time enhancing the performance, cutting the costs, and making it possible to take architectural innovations even further.

Why Is There a Need to Find Alternative Materials to Cement and Concrete?

Moving to materials for construction that are environmentally friendly is caused by a number of reasons, such as those that are related to the environment, economy, and the structure of buildings.

1. Environmental considerations

The traditional method of cement production includes heating limestone and clay to 1, 400, 1, 500C, which is an energy, intensive process and releases a huge amount of carbon dioxide. Furthermore, the extraction of raw materials such as limestone, sand, and gravel may lead to habitat loss, water pollution, and destruction of the landscape. Through the use of alternative materials, the construction sector can significantly lower its greenhouse gas emissions, save natural resources, and play a part in climate change mitigation.

2. Economic benefits

Some green alternatives are based on industrial leftovers or natural resources that can be much cheaper than new cement. For instance, fly ash, slag, silica fume, and rice husk ash are normally lower in price than conventional Portland cement. Besides that, the use of these materials helps to decrease the waste disposal costs for the industries that generate them as waste and at the same time may open an opportunity to getting green building incentives, grants, or tax reliefs.

3. Improved Material Performance

In certain cases, different substitutes have the capability not only to provide the same performance as traditional cement but also to surpass it. Alternative materials can bring about an improvement in the properties of durability, chemical resistance, impermeability or insulation. As an example, geopolymer concrete offers much more resistance to chemical attack, and hempcrete is great in providing natural insulation and breathability, thereby giving traditional concrete a run for its money in terms of benefits.

4. Resource Efficiency

Quite a few sustainable alternatives turn waste materials or agricultural byproducts into new uses, thus raising the principles of circular economy. In addition, by keeping waste away from landfills and decreasing the demand for virgin materials, these alternatives serve to preserve resources, all the while producing high, quality and durable building materials.

Popular Cement Substitutes

Fly ash

Fly ash is a very fine powder resulting from the combustion of coal in power plants. It contains a large amount of silica and alumina that, when combined with lime, makes a pozzolanic material forming extra cementitious products. It helps in enhancing the workability of the concrete, reducing its water requirement, increasing the strength at a longer period, and also lowering the heat released during hydration, thus lessening the thermal strain of big pouring. Fly ash finds extensive applications in bridges, dams, highways, and skyscrapers where the requisites of strength and durability are of topmost importance.

GGBS

GGBS is a by- product of the steel making process. When it is added to concrete after being ground very fine, a chemical reaction occurs with calcium hydroxide resulting in the formation of compounds that provide concrete with higher strength and durability. Besides being resistant to chemical and sulfate attacks, it also contributes to the enhancing of durability in aggressive environments and the prolonging of the structural life of the building. GGBS finds its applications in marine structures, coastal bridges, sewage treatment plants, and tunnels.

Silica FumeSilica

Silica FumeSilica fume is a secondary product of the extraction of silicon and production of ferrosilicon alloys. Its ultrafine particles help to make the concrete microstructure more compact. It raises compressive and tensile strength, lowers permeability, and hence increases the chemical resistance of the concrete. These are critical infrastructures such as skyscrapers, tunnels and heavy industrial floors.

Rice Husk Ash

Rice husk ash is acquired by incinerating rice husks, which is one of the most common by-products of agriculture. Since it has a high content of amorphous silica, it acts as an outstanding pozzolanic material. Besides improving compressive strength, it also reduces permeability and thus mitigates environmental impact by reusing the agricultural waste. RHA finds its main application in constructions of homes, public/commercial buildings, and works in the countryside, especially in places where it is a tradition to grow rice.

Limestone Calcined Clay Cement (LC3)

LC3 is a mix of calcined clay and limestone and it can be low, carbon cement with physical properties similar to those of normal Portland cement. Its production releases up to 40% less CO, it has strength and durability on par with that of conventional cement, and is cheaper because of the use of plentiful clay. LC3 is appropriate for ordinary building works such as urban residential housing, commercial buildings, and civil/public infrastructures.

Innovative Concrete Alternatives

Geopolymer concrete

Geopolymer concrete is made when fly ash or slag industrial wastes are chemically reacted with alkaline solutions. It is environmentally friendly as it cuts down CO emissions by 80% compared to the use of cement only. Geopolymer concrete is characterized by its outstanding fire resistance and good resistance to chemicals and sulfates. Besides, it has a low potential of shrinkage and cracking. Its use is recommended for installations exposed to chemical or high temperature harsh conditions such as paving industrial floors, sewage plants, and coastal projects.

Hempcrete

Hempcrete is a biocomposite made by mixing the woody core of hemp plants with lime. As a lightweight, insulating, and carbon, negative bio composite over its entire life, it offers natural thermal and acoustic insulation, is breathable and moisture regulating, and has low embodied energy. Hempcrete is suitable for energy, efficient home building, rural housing, and green design developments.

Recycled aggregate

Recycled aggregate concrete is essentially crushed concrete from demolished buildings that is reused as a replacement for virgin aggregates. It lowers the consumption of virgin materials, helps in waste reduction of the construction sector, and also decreases the transportation emissions. This kind of concrete can be used in road construction, residential buildings with low, to, medium load, and industrial flooring.

Magnesium cements

Magnesium cements chemically react with the carbon dioxide present in the atmosphere during the curing process, thus, instead of emitting carbon, they effectively sequester it. These cements can be carbon, neutral or even carbon, negative, in addition to being strong and long, lasting. Magnesium, based concrete finds its best use in precast components, panels, and carbon, neutral building projects.

Self- healing concrete

Bacterial or self- healing concrete uses bacteria that generate calcium carbonate when cracks occur and water enters. Such a tiny crack heals itself, the life of the structure is prolonged and the cost of maintenance is reduced. The use of this innovative concrete is obviously advantageous for bridges, tunnels, marine structures, and other infrastructural elements which need high, level maintenance.

How to Choose the Right Substitute?

The selection of an effective medium depends on:

- Environmental Conditions: Some materials, like hempcrete, work well in temperate climates but not in wet or cold climates.

- Structural Requirements: In high load-carrying structures, geopolymer concrete/GGBS might be used, whereas for housing, hempcrete/recycled aggregate might be used.

- Local Availability: By sourcing locally, the business will not incur transportation costs and will not contribute

- Lifecycle Considerations: Sustainability does not just mean materials; it also means durability and maintenance, often over decades.

Green Building Materials Potential in India

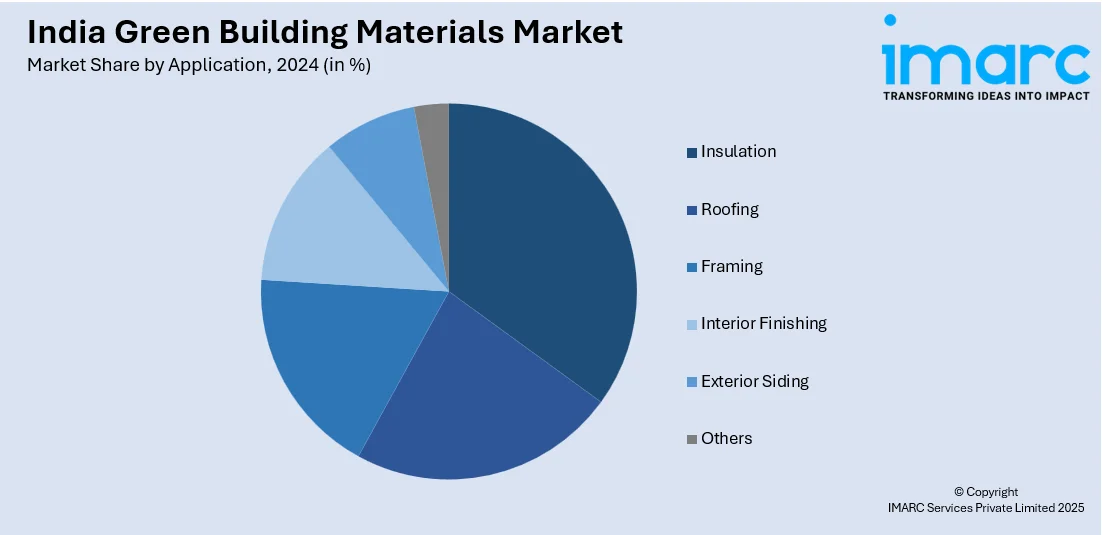

The India green building materials market size reached USD 13.86 Billion in 2024. Looking forward, IMARC Group expects the market to reach USD 39.01 Billion by 2033, exhibiting a growth rate (CAGR) of 11.28% during 2025-2033. The market is witnessing significant growth, driven by widespread adoption of energy-efficient and sustainable construction materials and escalating demand for recycled and locally sourced building materials.

In addition, the focus on green certifications such as Indian Green Building Council (IGBC) and Leadership in Energy and Environmental Design (LEED) is generating more urgency concerning the adoption of sustainable materials. For instance, according to industry reports, as of September 30, 2024, 95% of assets rated by Crisil Ratings are green-certified, with nearly 100% of office REIT stocks also achieving green certification. Developers seeking to comply with environmental regulations and meet consumer expectations for eco-friendly buildings are investing in innovative products like phase change materials (PCMs), low-emission paints, and recycled steel.

GBM Innovations in India’s Green Building Sector

India’s startup ecosystem is producing practical innovations in green building materials (GBMs). Hyderabad-based GreenJams makes “Agrocrete” blocks, the world’s first carbon-negative verified GBM, using crop residues and industrial by-products. Agrocrete can reduce construction costs by half and improve thermal insulation by 350%.

In Assam, Zerund converts plastic waste into lightweight bricks for housing, which have been used in Pradhan Mantri Awas Yojana (Urban) (PMAY-U) projects in the Northeast, showing GBMs can meet mass-housing standards. Bengaluru’s Biomart produces “plastic bricks” from recycled plastic, keeping waste out of landfills. Other startups are developing cow-dung insulating boards, microbially self-healing mortar, and agro-waste panels, such as Strawcture Eco’s wheat- and rice-straw panels with high insulation.

These examples show that the GBM ecosystem is creating materials that reduce emissions and costs while meeting local construction needs.

Real World Case Studies

1. Noida International Airport uses LC3 — India’s First Large‑Scale Use of Low‑Carbon Cement

One of the most prominent sustainability milestones in Indian infrastructure is the extensive use of Limestone Calcined Clay Cement (LC3) in the construction of the new Noida International Airport near Delhi. This material was used widely in the airport’s structures as part of its net‑zero emissions strategy.

Why it matters:

- LC3 is a low‑carbon alternative to traditional Portland cement, reducing CO₂ emissions by up to around 40% during production compared to conventional cement.

- It uses readily available limestone and calcined clay, lowering both production energy needs and costs.

- Its implementation on a major infrastructure project signals a shift toward sustainable materials in large‑scale public works across India and may influence broader industry adoption.

2. Green Geopolymer Concrete Research at Indian Institute of Technology Indore

Researchers at IIT Indore have developed a sustainable geopolymer concrete that significantly reduces carbon emissions while using industrial waste like fly ash and ground granulated blast furnace slag (GGBS).

Key outcomes:

- The geopolymer mix eliminates traditional cement altogether, lowering CO₂ emissions by up to 80% compared with conventional concrete.

- It reduces construction costs by approximately 20% and removes the need for water curing—a crucial advantage in regions with water scarcity.

- This concrete also develops rapid strength, making it suitable for urgent or temporary structures like military bunkers, emergency shelters, and infrastructure repairs.

3. Eco‑Houses Built from Ash by NTPC in Chhattisgarh

The state‑owned energy giant NTPC has developed eco‑friendly housing solutions using ash‑based construction materials from its power plants.

Project highlights:

- An “Eco‑house” in Sipat, Bilaspur district was constructed using interlocking wall blocks made from ash, eliminating the need for conventional sand, cement, steel, mortar, plaster, or putty.

- These ash products reportedly cut roughly 75% of carbon emissions compared to traditional housing methods.

- The modular design allows the house to be dismantled and reassembled, offering flexibility and future reuse, a unique sustainability feature.

This initiative shows how industrial byproducts can be repurposed into affordable, low‑carbon housing solutions, especially important for rural and low‑income communities.

4. Novacret (IISc‑Incubated Startup) Pilot Projects in Bengaluru

The eco‑tech startup incubated at the Indian Institute of Science (IISc) in Bengaluru is actively testing geopolymer‑based sustainable cement alternatives in real urban settings.

Pilot applications:

- The startup has installed footpaths and bus stops in neighborhoods like Vijayanagar and Govindrajnagar using geopolymer materials developed from fly ash and GGBS—substituting traditional OPC cement.

- According to the developers, these materials achieve full strength much faster (about 3 days) in India’s tropical climate compared to the standard 28‑day curing time for ordinary concrete.

- The startup is also exploring porous blocks that enable rainwater to infiltrate the ground, helping reduce urban flooding while improving groundwater recharge.

This example shows how innovative companies are already integrating sustainable mixtures into everyday urban infrastructure and how new products can offer additional environmental benefits like stormwater management.

Challenges in Adoption of Alternative Materials

- Regulatory Hurdles: Building codes favor traditional materials, which may require additional certification**

- Availability: Some materials, for instance, fly ash/rice husk ash, might be location-specific.

- Performance Variability: The performance of substitutes is not necessarily constant across climates and structural use

- Technical Knowledge: Proper mix design and expertise are necessary to achieve expected performances.

Way Forward

The construction industry is at a crossroads, with traditional cement and concrete having been good contributors to human development, but their environmental impact is so detrimental that an alternative, such as fly ash, LC3, geopolymer concrete, hempcrete, magnesium-based cements, and bacterial concrete, does not just assist in cutting carbon emissions, but also helps in improving the longevity or performance of a building.

Therefore, by making an informed decision regarding the materials based on the climatic, architectural, and available features inherent in various building materials, architects, engineers, and builders can create buildings that not only prove to be useful and safe structures but also environmentally friendly. This way, each advancement towards a greener construction leaves a precedented example that moulds our world into a state where our cities and buildings are as green as they are strong.

.png)