Cladding is much more than a building’s exterior decoration, it provides essential protection against weather, enhances thermal efficiency, and improves acoustic comfort. At the same time, cladding forms a continuous layer over floors and windows, which means that if it is made from flammable materials, it can quickly become a conduit for fire and hot gases to travel up the building’s exterior. Tragic incidents around the world have shown how combustible cladding can transform a fire in a single apartment into a disaster that engulfs an entire high-rise within minutes. This makes selecting fire-resistant materials and designing façades thoughtfully a critical component of high-rise safety.

Fire-resistant cladding thus goes beyond being a mere choice of material; it is a decision that affects the survival of human lives. The authorities are more and more stringent in the way building regulations distinguish external walls along with their parts (insulation, substrate, fixings and finishes) as one of the main elements of fire strategy. One must not forget that while the architects and developers choose the right material for cladding, their decision bears not only aesthetic, thermal and durability aspects but also the crucial tested fire behaviour factor.

How fire performance is defined

The fire behaviour of cladding is gauged through two primary methods:

- Reaction to fire - the material's behaviour when confronted with heat or flame (does it catch fire, drip, discharge heat or smoke?). Usually, such response is communicated via letter ratings like A, B, C, etc., or terms like non-combustible and limited combustibility.

- Fire spread on the façade - the functioning of a single system in the scenario of fire starting at one level: is vertical or horizontal flame spread across the façade allowed? The tests reproduce fires at windows or openings and notice the quickness of the exterior.

Full compliance cannot overlook the interplay of both factors: a panel might be considered non-combustible, however, if the insulation behind it is combustible, then the façade would still not pass in the event of a real fire.

Materials that perform well (and why)

Mineral-Based Systems (Stone, Terracotta, Fiber-Cement)

Mineral-based cladding materials that include natural stone, terracotta, and fiber-cement panels are referred to as the most safe materials in terms of fire safety. These materials are non-combustible by nature, which means they do not catch fire and do not emit harmful gases when heated. As a result of their solid structure, they are able to resist the heat and thus slow down the fire spreading on the outer surface of the building. Besides fire-resistance, stone and terracotta exterior walls also provide toughness and long-lasting weather-resistance, thus, they are perfect for the use in high-rise buildings. Moreover, fiber-cement panels are a multi-functional product offering a stylish contemporary appearance while still being highly fire-resistant. The only drawback is that these materials are heavier and need a strong support structure, however, their eventuality under fire makes them a loyal pick for saving lives and meeting regulations.

Metal Cladding (Aluminum, Steel, Zinc)

In vogue architecture, metal cladding is a significant reason for the attractive and flexible nature of the design. Non-combustible materials such as aluminum, steel, and zinc can endure high heat without bursting into flame. Nevertheless, a metal façade's safety is very much dependent on the way it is put together. In the case of composites like Aluminum Composite Material (ACM), the middle layer is the one that matters most - a polyethylene core is flammable and not safe for tall buildings while a mineral-filled or non-combustible core is safe even in a fire. Metal façade units made from metals can bring the great combo of beauty,环保, and fire resistance if they are properly planned and executed, which is why they are the first choice of most contemporary high-rise projects.

Non-Combustible Core Insulated Panels (Mineral Wool Insulation)

Façade insulation systems with mineral wool as a core or backing offer a good balance of energy-saving and fire security. Mineral wool is a product of volcanic rock or slag and is very resistant to fire, it keeps its shape even in very hot conditions. It stops vertical flame spread and reinforces the support structure, thus the fire is able to break through the façade for a shorter period. Besides, this material has good acoustic and thermal properties, thus it also helps to improve the overall building performance. When the mineral wool is used as the backing of stone, metal, or fiber-cement cladding, it is an invisible but very important fire-resisting layer that ensures the efficiency and safety of the façades. Also, the correct installation and pacing, especially the moisture protection, is the key to its effectiveness during the whole lifespan of the building.

Terracotta and Ceramic Rainscreens

One of the major advantages that terracotta and ceramic rainscreen provide is the perfect harmony between good looks and reliable fire safety. Made from the same earth, the similarities between the two are also pretty much identical in terms of properties. So, they are completely non-combustible and can keep being functional even at extremely high temperatures. Besides being fire-resistant, they are extremely durable and weather-resistant, too, but their warm colors and textures provide an organic character to the new buildings. In most cases, terracotta façades are ventilated rainscreen assemblies, which means that air can flow behind the panels to take away moisture without risk of fire. Yes, they are a little bit heavy and fragile at the time of installation, however, their resistance over time, and natural fire-resilience, make them one of the safest choices for high-rise architecture.

Glass and Glazing Systems (Fire-Rated Options)

One of the most attractive features of the modern city skyline is glass facades, however, their fire performance is dependent on the type of glazing system employed. Simple glass breaks very fast when subjected to high heat, thus, it allows the fire and smoke to escape. The glass used in fire situations, however, is manufactured in such a way that it can resist high temperatures and maintain its structure for a certain period, therefore, it helps in containing the fire within a compartment. These particular units are tested as whole units, which include not only the glass but also the frames and seals, thus, they assure the performance during the occurrence of fires. If carefully incorporated in a building's fire plan, the fire-rated glass can give the right balance of visibility, safety, and design expression - especially in the areas around stairs, corridors, and emergency exits.

Intumescent Coatings and Fire-Retardant Treatments

When architects pick out such materials as wood or composites for their inherent warmth and attractive looks, intumescent coatings can be the fire protection that is less obvious but just as effective. Intumescent paints expand on heat and form a carbon layer that is thick and has low thermal conductivity from which the heat transfer and the spread of fire are stopped. This failure, however, is only temporary but still able to hold back fire long enough for the evacuation process and rescuing to take place thus, the overall safety is enhanced, and the material's original look is not changed almost at all. Intumescent treatments are the main safety feature of hybrid façades or flammables-included accent panels. Besides, their usefulness is not quite out of the question as they are also a valuable secondary fire-resisting system in the fire-safe design and in need of a certain re-application and maintenance over time.

Timber Cladding (Treated Wood, Cross-Laminated Timber, Engineered Wood)

Timber is a material that can easily catch fire since it is a natural combustible. Nevertheless, timber can be a higher fire-performance material if it is properly treated with fire-retardant coatings or if an engineered form like a cross-laminated timber (CLT) or a fire-resistant laminated wood is utilized. Fire-retardant treatments on timber help to slow the burning of the material, reduce the production of smoke, and allow for more time to evacuate the area in the event of a fire. Besides, timber is the most aesthetically pleasing material that provides not only the warmth and versatility but also the sustainability benefits because it is a renewable resource. The main issues are proper detailing, compliance with fire safety regulations, and the use of a layer of non-combustible backing or insulation (for instance, mineral wool) to improve the safety of the whole façade. The result is a timber façade that is visually attractive and has a safety level that is acceptable for even mid-rise and, in some cases, high-rise buildings when the regulations and engineering permit.

Materials to be cautious about

- Polyethylene-cored ACM panels (plastic core): a lightweight, cheap, and visually attractive solution but highly infamous for the quick spreading of the flame in façade fires. So a high-rise external walls should not be used unless the core is changed with mineral materials and fully tested as a system.

- Unspecified insulated foam (e.g., PIR, EPS) without fire barriers: These are capable of providing great thermal performance, however, they are likely to ignite vigorously unless protec

Testing standards — what to ask for?

When you are selecting cladding, it is not sufficient just to know what the panel is made of. You have to provide proof of testing at the system level. The main things to request from manufacturers and suppliers are:

- Reaction to fire classification (e.g., Euroclass A1/A2 for non-combustible or limited combustibility, national equivalents).

- Large-scale façade test reports that show new, or real, façade constructions, with fixings, cavities and insulation, being tested (these show how the whole system behaves).

- Fire propagation and vertical spread test certificates relevant to your jurisdiction.

- Thermal barriers, cavities and compartmentation — the substrate, air gap, insulation and fixings: how they perform together.

- Third-party certification — Besides manufacturer tests, look for independent labs and accredited bodies.

- Warning: an individual panel tested alone is not equal to the panel plus insulation plus cavity and fixings tested together.

Design and installation considerations

For highly flammable situations, decide on the use of non-combustible core materials: For tall buildings, the default setting shall be non-combustible cladding systems with mineral insulation cores.

- Control vertical cavities: Air gaps that go up-and-down can easily turn into chimneys. At every floor, around openings and at compartment boundaries place cavity barriers and fire stops.

- Protect openings and junctions: Windows, vents and wall junctions are the weak spots — put fire-rated seals and tested transoms to keep compartmentation intact.

- Work with tested system assemblies: Be full system test reports the main requirement — not just component declarations. Certify that the method tested is the one the installers use.

- Support and fixing details: Metal brackets can be a way to transfer heat; thermal breaks and non-combustible supports lessen the danger and stop the unexpected failure from occurring.

- Think of maintenance and inspections: The fire performance can be lowered by incorrect retrofits or the natural wear of the façade. Plan regular façade inspections and take care of your coatings and seals.

- Make provisions for retrofits: While upgrading older buildings, do not just put on new cladding without examining the whole wall assembly. Most of the compliance failures that are result of retrofit projects.

Regulatory compliance and documentation

Even though the requirements of the fire codes differ from country to country and region to region, the main points are the same: those codes place higher safety loads on taller buildings, require non-combustible façades after a certain height and demand the documented proof of performance. As a condition, developers must have and keep a fire compliance file which contains:

- Design drawings and specifications of the cladding assembly.

- Complete test reports and certificates of the system.

- Installation records and as-built drawings.

- Inspection and maintenance records of the ongoing work.

Practical recommendations

- Use non-combustible panels and mineral wool insulation for buildings above 18–30 meters (or local height threshold).

- Ensure third-party certification and full façade system testing for all cladding materials.

- Install cavity barriers at every floor level and around all openings to prevent vertical fire spread.

- Avoid ACM panels with polyethylene cores and any unprotected combustible insulation on high-rise exteriors.

- Maintain a comprehensive fire compliance file at handover, documenting tested materials, installation details, and certifications.

- Conduct regular façade inspections and reapply intumescent coatings or fire-retardant treatments as part of the ongoing maintenance schedule.

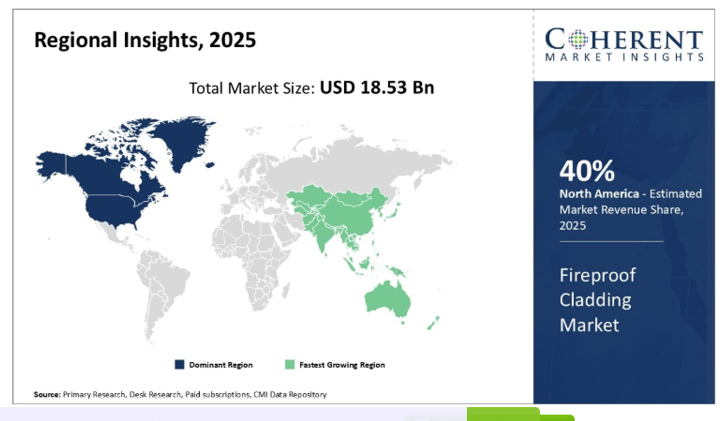

Rising Demand for Fire-Safe Cladding Globally and India

As per Coherent Market Insights, the market potential for fire-resistant cladding is substantial, with projections for the global market to grow from approximately $26 billion in 2023 to over $71 billion by 2029, driven by stricter fire safety regulations, increasing urbanization, and a demand for sustainable building practices. Key factors fueling this growth include robust government initiatives in regions like Asia-Pacific and Europe, rising investments in commercial and residential construction, and the increasing need for high-performance materials in modern buildings.

The market for fire-resistant cladding materials in India is experiencing significant growth, driven by stricter fire safety regulations, rapid urbanization, and a booming construction sector, particularly in high-rise and commercial buildings. Government focus on safety, coupled with rising demand for energy-efficient and sustainable building materials and smart city initiatives, is creating strong momentum in the sector. Stringent regulations are compelling developers to adopt fire-resistant materials, while large-scale infrastructure projects in major cities like Mumbai, Delhi, and Bangalore are fueling demand further. At the same time, growing public and industry awareness of fire hazards is encouraging the use of protective materials across residential, commercial, and industrial sectors. Initiatives such as Make in India are supporting domestic manufacturing and technology development for passive fire protection solutions, further strengthening the market.

Commercial buildings currently dominate the application landscape, but residential and industrial sectors are emerging as important growth areas. While traditional materials remain in use, modern alternatives like fiber cement panels, mineral wool insulation, and aluminum composite panels are increasingly being adopted due to their safety, durability, and energy efficiency. Geographically, Western India, with its high concentration of industrial and commercial activity, continues to be a dominant market. Overall, the combination of regulatory support, urban expansion, and a focus on sustainable development positions India’s fire-resistant cladding market for robust growth, with modern materials offering an effective balance between safety, performance, and aesthetics.

Leading Fire-Resistant Cladding and Facade Manufacturers in India

- Viva ACP (Mumbai) – Produces fire-retardant aluminium composite panels with non-combustible cores.

- Aludecor (Kolkata) – Manufactures fire-safe ACP panels certified to international standards.

- Eurobond (Gujarat) – Offers fire-resistant aluminium composite panels for high-rise buildings.

- Ameetuff Technical Coatings (Haryana) – Provides fire-retardant paints and coatings for walls and steel.

- HIL Ltd (Hyderabad) – Produces non-combustible fibre-cement boards and façade panels.

- Frontier Polymers (Punjab) – Manufactures fire-retardant resin-based cladding materials.

- Fundermax India (Bengaluru) – Supplies exterior wall panels with fire protection.

- Armstrong World Industries India (Pune) – Makes mineral-based fire-rated ceiling and wall systems.

- Alutuff (India) – Produces fire-resistant wall and façade panels with mineral cores.

- Alstone India – Offers aluminium composite panels tested for fire safety.

- Everest Industries Ltd – Provides moisture- and fire-resistant fibre cement boards for façades.

- Wedge India – Manufactures non-combustible wall panels for building exteriors..

Balancing safety and design

Fire-resistant cladding should not weigh down the looks of the building only, it is a moral and legal obligation besides that. One of the beauties of modern architecture is that it can most of the time - - result in gorgeous, energy-saving façades which are not at the expense of safety. The trick is to manage the the façade as a system: getting tested materials, enforcing entire system testing, carefully drawing each connection and cavity, and closely following the maintenance routine. Facades, in which the safety notion is foremost in the minds of the architects, engineers, contractors and building owners, become not only expressive but also dependable , a combination that each and every occupant can enjoy in peace of mind.

.png)